Call: 07971258664

MOQ : 1 टुकड़ा

About

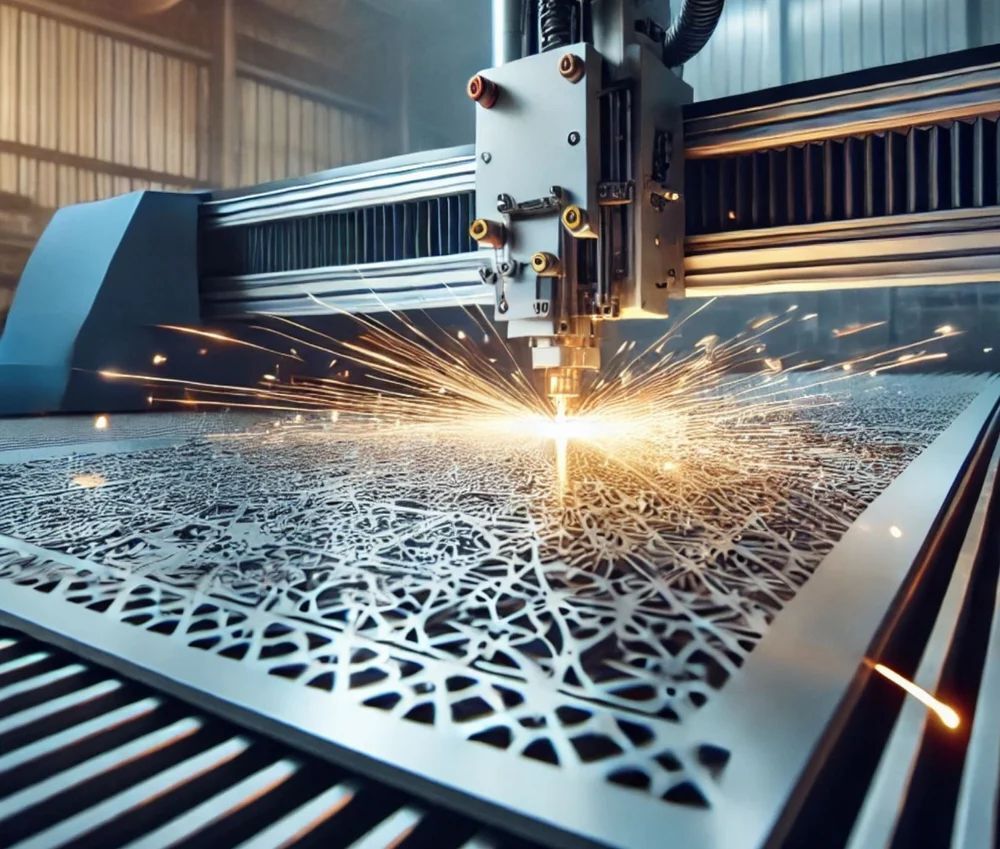

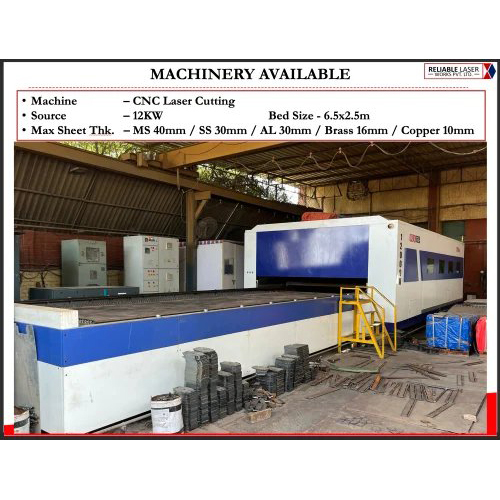

Copper laser cutting services involve precision cutting of copper sheets, tubes, and components using advanced laser technology. This process is ideal for custom fabrication and industrial projects, ensuring clean edges, accurate dimensions, and minimal material waste.

Key Features- Precision Cutting: Accurate cuts with minimal waste and high-quality finishes

- Customization: Tailored cutting solutions for specific project requirements

- Material Versatility: Cutting services for copper sheets, tubes, and components

- Efficient Turnaround: Quick turnaround times and flexible production capacities

Applications- Industrial Manufacturing: Cutting components for machinery, automotive, and aerospace industries

- Architectural Design: Creating intricate designs and patterns for building facades and interiors

- Prototyping and Modeling: Rapid prototyping and model making for product development

Benefits- Cost-Effectiveness: Reduced material waste and lower production costs

- High-Quality Finishes: Smooth edges and precise cuts for improved product quality

- Increased Productivity: Efficient cutting processes and reduced production times

Some notable service providers include

- Bhoomi Engineering: Offers precision CNC laser cutting services for copper and other metals

- Spak Metal Crafts: Provides high-quality copper laser cutting services with customized designs

- Microlaser: Offers copper laser cutting solutions with advanced technology and expertise

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें