Call: 07971258664

Price 100000 आईएनआर/ टुकड़ा

MOQ : 1 टुकड़ा

Trade Information

- Minimum Order Quantity

- 1 टुकड़ा

- आपूर्ति की क्षमता

- प्रति दिन

- डिलीवरी का समय

- दिन

- नमूना नीति

- मुख्य निर्यात बाजार

- मुख्य घरेलू बाज़ार

About

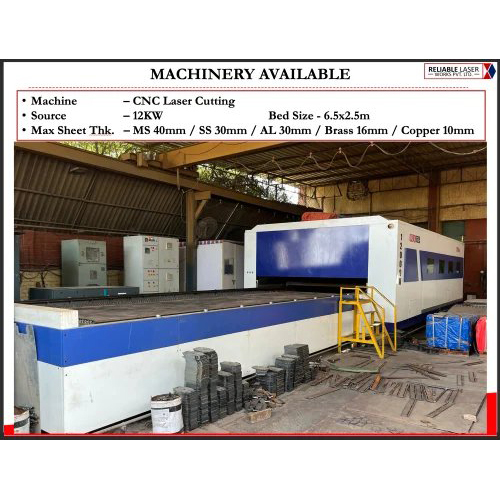

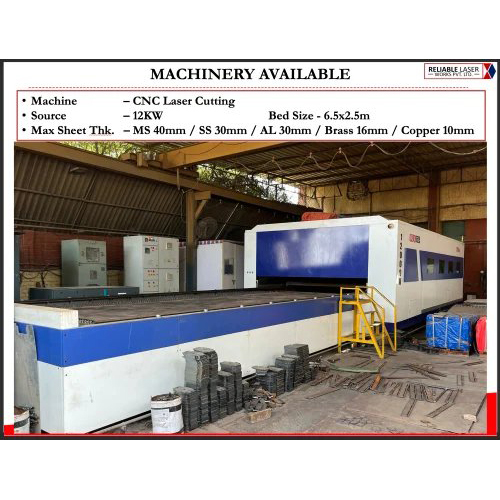

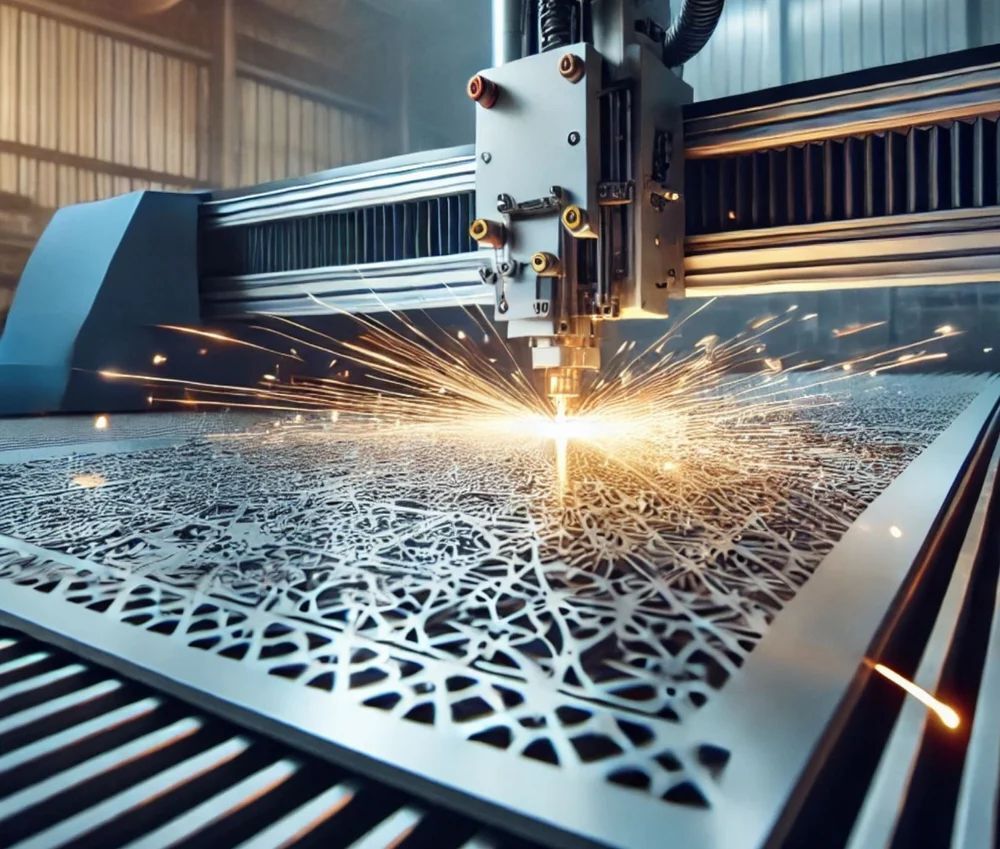

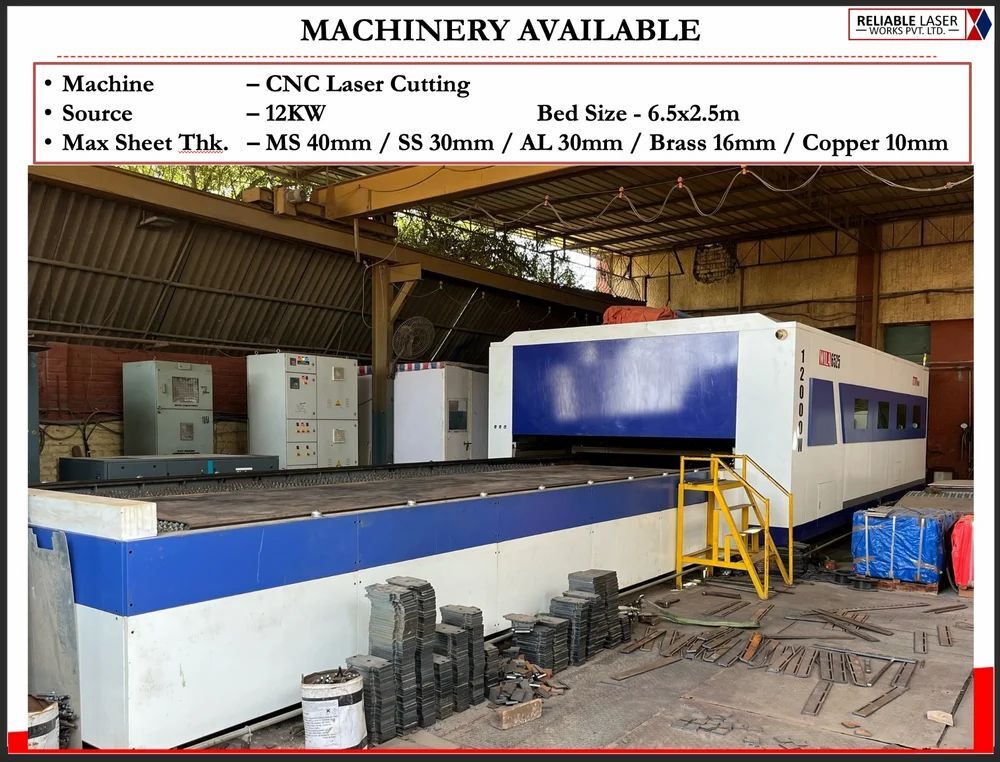

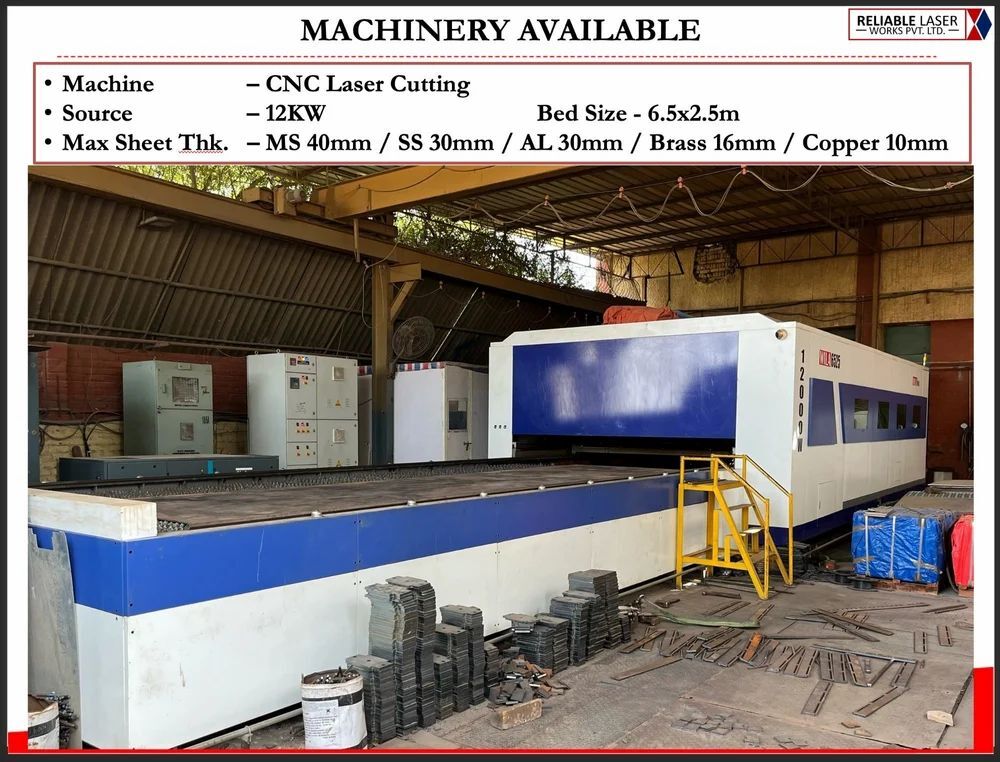

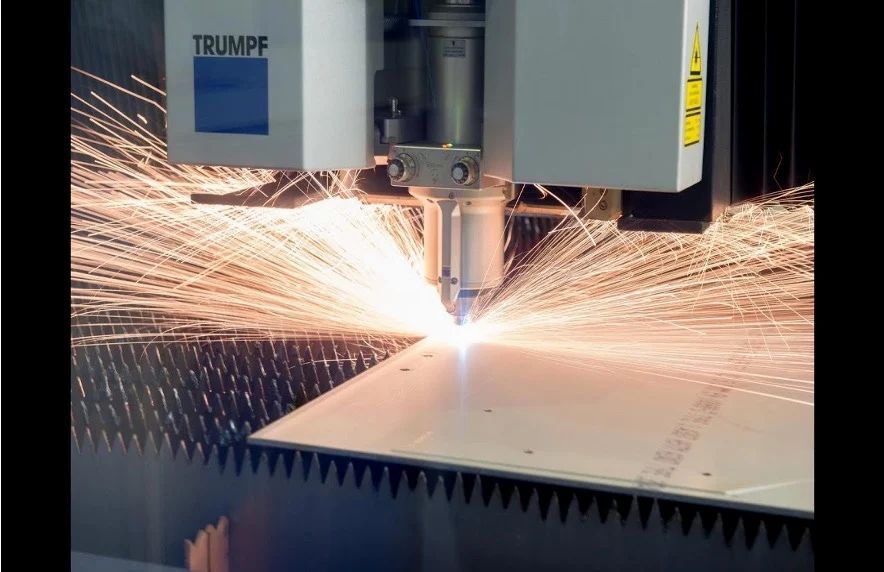

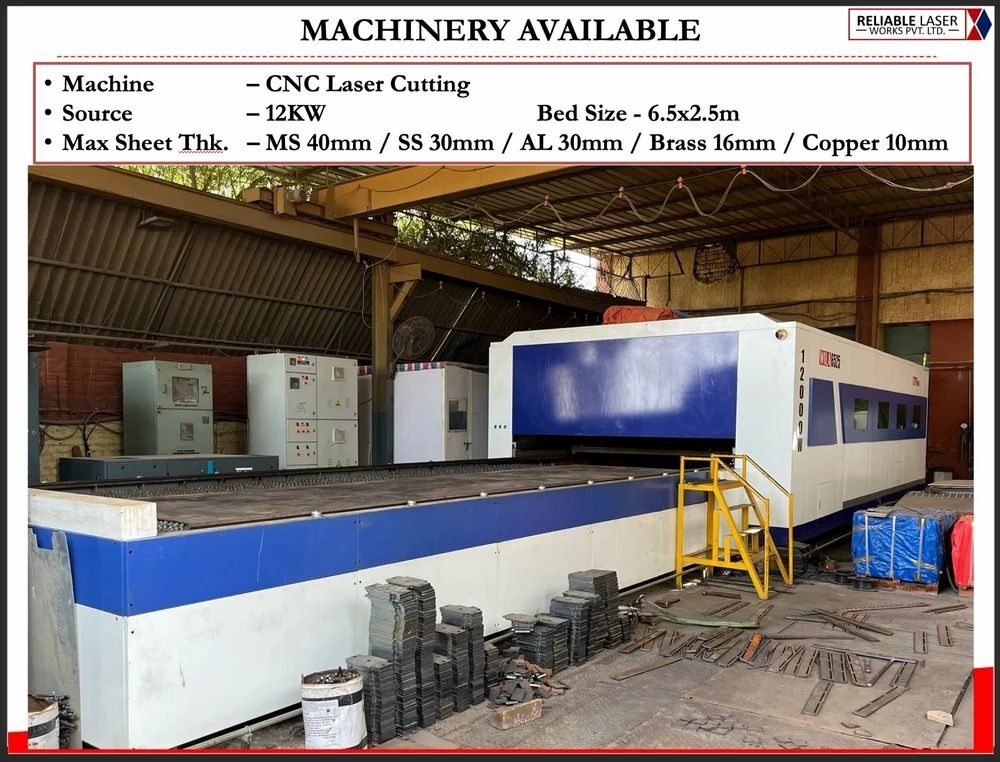

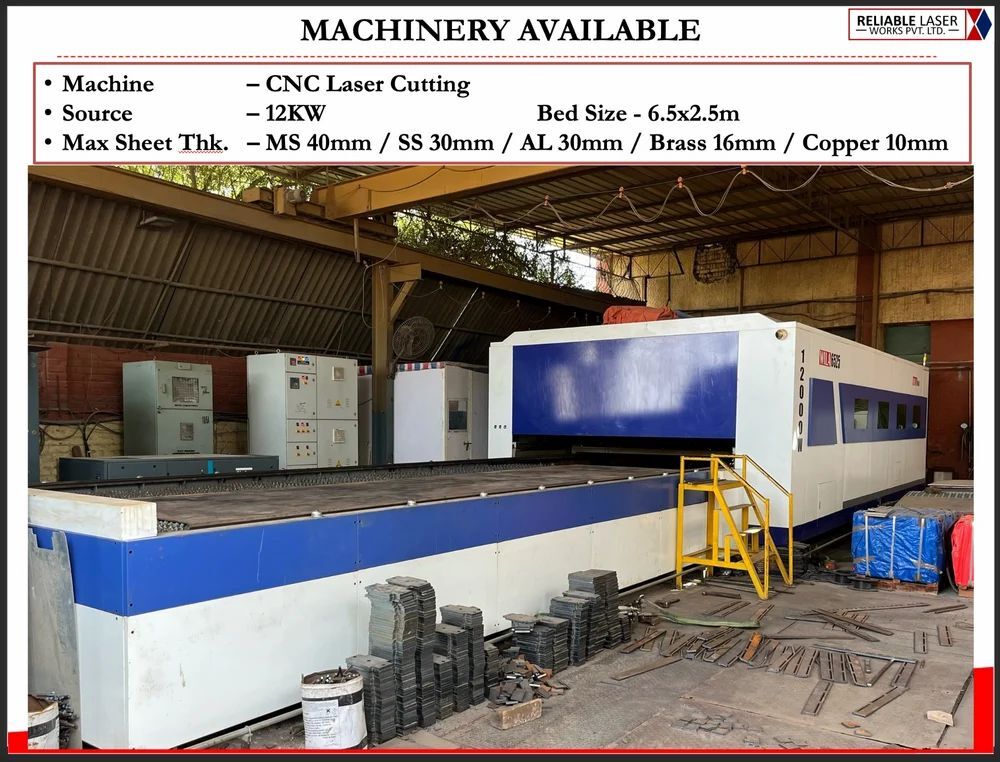

MS Sheet Laser Cutting सेवाएं involve precision cutting of Mild Steel (MS) sheets using advanced laser technology. This process is ideal for custom fabrication and industrial projects, ensuring clean edges, accurate dimensions, and minimal material waste.

Key Features- Precision Cutting: Accurate cuts with minimal waste and high-quality finishes

- Customization: Tailored cutting solutions for specific project requirements

- Material Versatility: Cutting services for various materials, including steel, aluminum, and copper

- Efficient Turnaround: Quick turnaround times and flexible production capacities

Applications- Industrial Manufacturing: Cutting components for machinery, automotive, and aerospace industries

- Architectural Design: Creating intricate designs and patterns for building facades and interiors

- Prototyping and Modeling: Rapid prototyping and model making for product development

Benefits- Cost-Effectiveness: Reduced material waste and lower production costs

- High-Quality Finishes: Smooth edges and precise cuts for improved product quality

- Increased Productivity: Efficient cutting processes and reduced production times

Service ProvidersSome notable service providers include

- Keddy Concept: Mumbai-based provider offering MS laser jali cutting services

- Galaxy Laser Works: Delhi-based provider offering modular MS sheet CNC laser cutting services

- S.S. Industries: Faridabad-based provider offering MS sheet laser cutting services

Exceptional Precision and Versatility

Our MS Sheet Laser Cutting Service is engineered for projects requiring tight tolerances and intricate details. With precise 0.2 mm tolerance and high-edge clarity, it supports diverse applications, from prototypes to mass production. Both single and batch orders are accommodated, providing tailored solutions for industries like automotive, construction, and engineering.

Comprehensive Customization and Finishing

Clients can submit their unique designs for complete customization. Post-processing options such as bending, welding, and powder coating are available to deliver a ready-to-assemble product. This all-in-one service streamlines your supply chain, saving you both time and logistical effort.

Quick Turnaround and Nationwide Coverage

With advanced technology and efficient workflows, bulk orders are processed within 2-7 days, ensuring rapid delivery. Located in India, we cater to both local and national clients, guaranteeing consistent quality and reliable lead times for every order, regardless of size.

FAQs of MS Sheet Laser Cutting Service:

Q: How does the MS Sheet Laser Cutting process ensure precise results?

A: Our laser cutting process utilizes advanced machines capable of maintaining a precision tolerance of 0.2 mm, delivering highly accurate cuts and clean edges even for intricate parts and holes as small as 1 mm in diameter.Q: What types of customization are available for laser-cut MS sheets?

A: We offer tailored solutions based on your drawings and specifications. You can request custom shapes, sizes, and design features, as well as optional post-processing such as bending, welding, and powder coating to meet your specific requirements.Q: When can I expect my bulk order to be completed and shipped?

A: Lead times for bulk orders are typically between 27 days, depending on order complexity and volume. Our streamlined workflow ensures your products are delivered promptly without compromising on quality.Q: Where can this MS Sheet Laser Cutting Service be accessed?

A: Our services are available to clients across India. We support various industries by providing reliable shipping and support nationwide, ensuring you receive your orders wherever you are located.Q: What is the process for placing an order or requesting a quote?

A: Clients simply need to provide drawings or specifications. Our team will review your requirements, offer a detailed quote, and guide you through the order processincluding any customization and finishing options you may need.Q: How can laser-cut MS sheets be used across industries?

A: Laser-cut MS sheets serve numerous applications such as automotive parts, construction profiles, machinery components, and custom fabrication projects, making them versatile solutions for manufacturers and suppliers.Q: What are the key benefits of choosing this laser cutting service?

A: Clients gain access to precise, high-quality cuts, rapid lead times, full customization, and optional finishingall handled by an experienced manufacturer and supplier in India, supporting efficient and reliable project delivery.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें